Advantages: Effectively protect the taste of food. Cool in gradually to prevent the container from the bottle breaking caused by the mutation of thermal stress.

|

Operation mode and working principle |

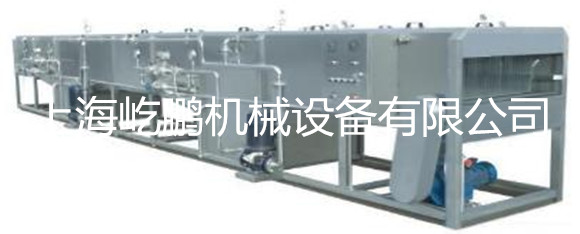

Adopt multi-stage treatment with hot water circulation spray sterilization, warm water precooling, cold water cooling. The sealed cans (bottles) are conveyed through the conveyor belt, enter the tunnel pasteurizer, through the preheating stage, heating stage (sterilization stage) and the cooling stage. |

|

Optional sterilization temperature and time |

Sterilization temperature and time are adjustable, bactericidal performance are stable |

|

Suitable range |

Pasteurization of various cans, PET bottles, glass bottles and other bottled beverages. |

|

The main components |

Spray nozzle system, mesh conveyor belt, speed-variable motor |

主要技術(shù)參數(shù)Main Technical Parameters

|

Production capacity(T/H) |

Equip according to the production capacity of sealing machine |

|

Sterilization Section |

3-5 sections |

|

Sterilizing temperature(℃) |

≤100℃ |

|

Steam Pressure |

0.4Mpa |

|

Dimension |

According to the production capacity |